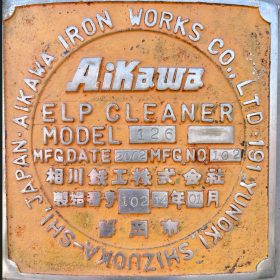

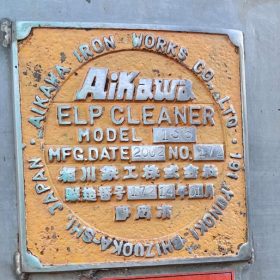

This listing features a used Aikawa ELP Cleaner, manufactured by Aikawa Iron Works Co., 株式会社. (Japan), a global leader in pulp screening and cleaning technologies. The ELP Cleaner is designed for efficient removal of heavy contaminants such as sand, metal particles, and other high-density impurities from pulp slurry, ensuring stable paper machine operation and improved pulp cleanliness.

These units are built with robust stainless-steel construction and are widely used in kraft pulp mills, recycled fiber lines, OCC systems, and stock preparation processes.

Available Models:

Q1: What types of used paper machines do you supply?

We supply a full range of used pulp, paper & board manufacturing equipment, including:

- Complete used paper machines

- Used pulp mill equipment

- Yankee dryers & dryer cylinders

- Calenders, coaters, rewinders,sheet cutters

- Used spare parts & auxiliary equipment

All equipment comes from reputable global brands and closed or upgraded paper mills.

第2四半期: What is the condition of your used paper equipment?

Our machines are mainly sourced from well-maintained operating mills, production upgrades, or factory closures.

Every machine is:

- Professionally inspected

- Technically evaluated

- Optionally refurbished and repainted

to ensure stable operation and reliable performance.

Q3: Do you provide refurbishment and rebuilding services?

はい. We offer:

- Mechanical refurbishment

- Bearing replacement

- Roll regrinding

- Full machine repainting

- Electrical & control system upgrades

Q4: Do you provide dismantling and installation services?

はい. We have professional engineering teams for:

- On-site dismantling

- Export packing & container loading

- Overseas installation supervision

- Commissioning & start-up support

Q5: Do you provide warranty for used paper machines?

はい. We provide a limited warranty for refurbished equipment, depending on machine type and condition.

Warranty details are clearly stated in each quotation.

Q6: How long is the delivery time for used paper machines?

Delivery time depends on:

- Machine condition (as-is or refurbished)

- Dismantling schedule

- Shipping destination

Normally, delivery time ranges from 70 to 90 days.

Q7: Can I inspect the machine before purchase?

はい. Customers are welcome to:

- Visit our warehouse

- Inspect machines at mill sites

- Receive detailed photos, videos, and inspection reports

Q8: What payment terms do you accept?

Common payment terms include:

- T/T (Telegraphic Transfer)

- L/C at sight

- Negotiable terms depending on project size

安全を提供します, プロ, すべての機器が完璧な状態で工場に届くことを保証する信頼性の高い梱包ソリューション. 各コンポーネントは標準的な輸出用木製ケースを使用して安全に梱包されています, 鉄骨フレーム, 必要に応じて防湿包装.

当社の物流チームが海上輸送をタイムリーに手配します, 土地, または顧客のニーズに応じて空気. 当社は信頼できる国際貨物運送業者と協力してスムーズな配送を保証します, 正確な文書化, そして定刻通りに到着.

古紙パルプ工場機械 & 機器サプライヤー

古紙パルプ工場機械 & 機器サプライヤー