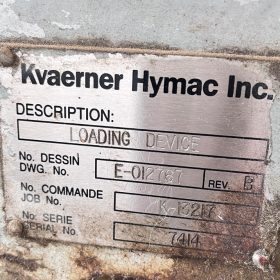

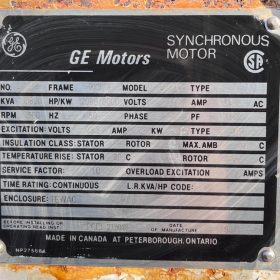

This listing features a used Kvaerner Hymac HSD-64 high-consistency refiner system, complete with the original Loading Device and a heavy-duty GE synchronous motor. Manufactured in Canada, Kvaerner refiners are well-known for their durability, high production efficiency, and long operational life in pulp & paper mills worldwide.

These HSD-64 refiners are suitable for processing wood pulp, recycled pulp, or mechanical pulp applications requiring precise refining control and stable fiber development.

Main Components Included

Applications

-

High-consistency mechanical pulp refining

-

Recycled fiber refining

-

TMP/CTMP production lines

-

Pulp preparation systems in kraft or paper mills

Condition

-

Used condition; suitable for refurbishment

-

Housing, bearing seats, and structure appear intact

-

Motors and loading units included as shown

These units are ideal for mills seeking a cost-effective replacement refiner set or for spare parts inventory.

Q1: What types of used paper machines do you supply?

We supply a full range of used pulp, paper & board manufacturing equipment, including:

- Complete used paper machines

- Used pulp mill equipment

- Yankee dryers & dryer cylinders

- Calenders, coaters, rewinders,sheet cutters

- Used spare parts & auxiliary equipment

All equipment comes from reputable global brands and closed or upgraded paper mills.

Q2: What is the condition of your used paper equipment?

Our machines are mainly sourced from well-maintained operating mills, production upgrades, or factory closures.

Every machine is:

- Professionally inspected

- Technically evaluated

- Optionally refurbished and repainted

to ensure stable operation and reliable performance.

Q3: Do you provide refurbishment and rebuilding services?

Yes. We offer:

- Mechanical refurbishment

- Bearing replacement

- Roll regrinding

- Full machine repainting

- Electrical & control system upgrades

Q4: Do you provide dismantling and installation services?

Yes. We have professional engineering teams for:

- On-site dismantling

- Export packing & container loading

- Overseas installation supervision

- Commissioning & start-up support

Q5: Do you provide warranty for used paper machines?

Yes. We provide a limited warranty for refurbished equipment, depending on machine type and condition.

Warranty details are clearly stated in each quotation.

Q6: How long is the delivery time for used paper machines?

Delivery time depends on:

- Machine condition (as-is or refurbished)

- Dismantling schedule

- Shipping destination

Normally, delivery time ranges from 70 to 90 days.

Q7: Can I inspect the machine before purchase?

Yes. Customers are welcome to:

- Visit our warehouse

- Inspect machines at mill sites

- Receive detailed photos, videos, and inspection reports

Q8: What payment terms do you accept?

Common payment terms include:

- T/T (Telegraphic Transfer)

- L/C at sight

- Negotiable terms depending on project size

We provide safe, professional, and reliable packing solutions to ensure all equipment reaches your mill in perfect condition. Each component is securely packaged using standard export wooden cases, steel frames, or moisture-proof wrapping as required.

Our logistics team arranges timely delivery by sea, land, or air according to customer needs. We work with trusted international freight forwarders to guarantee smooth shipping, accurate documentation, and on-time arrival.

Used Pulp Paper Mill Machinery & Equipment Supplier

Used Pulp Paper Mill Machinery & Equipment Supplier